10 reliable qualities to look for in cnc milling services near me

Discover the Benefits of Using CNC Machining Providers for Precision Design and Production

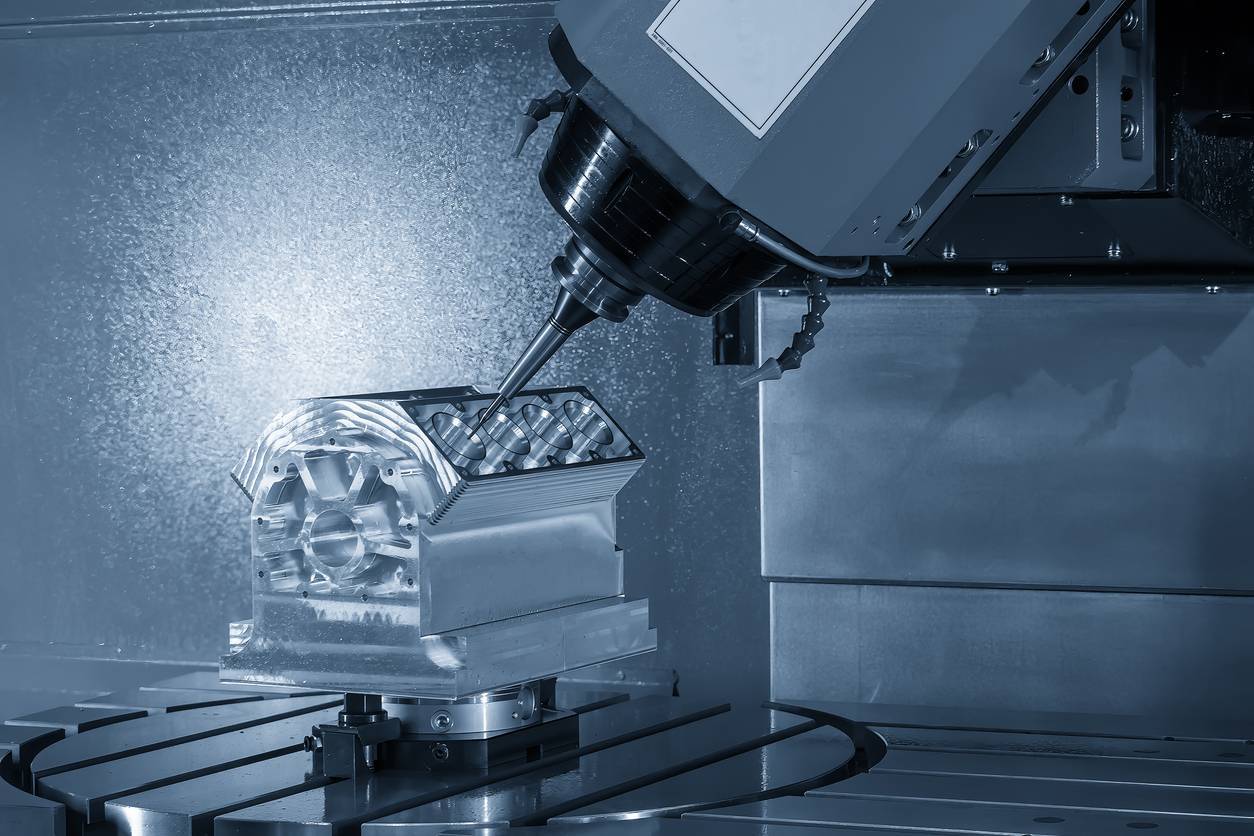

CNC machining services use considerable advantages for accuracy design and production. By using innovative computer-controlled equipment, these services ensure high levels of accuracy and performance. This technology enables the production of complex components from numerous products, minimizing human error and production time. The advantages prolong beyond accuracy alone, hinting at much deeper impacts on efficiency and cost-efficiency that are crucial for modern-day industries. Discovering these facets reveals a more considerable understanding of CNC machining's role.

Enhanced Precision and Accuracy

As sectors significantly demand higher standards, CNC machining solutions have actually become a vital service for attaining boosted precision and accuracy in engineering applications. These solutions use innovative computer-controlled machinery to produce intricate elements that fulfill stringent requirements. The capability to program precise dimensions decreases human error, ensuring that each part is manufactured to exacting tolerances.

CNC machining is especially beneficial in markets such as aerospace, auto, and clinical gadgets, where precision is vital. The modern technology enables for the creation of complex geometries that typical machining methods might struggle to achieve. By employing CAD models, CNC devices can reproduce layouts with exceptional fidelity, causing constant top quality throughout production runs.

Raised Effectiveness and Productivity

CNC innovation permits for the simultaneous processing of multiple components, leading to higher manufacturing prices. The capability to run makers continuously, even during non-working hours, maximizes operational time and resource use. In addition, the quick configuration and transition times connected with CNC machining facilitate rapid adaptation to different project requirements, enabling producers to respond quickly to market demands.

Affordable Manufacturing Solutions

CNC machining allows for quick prototyping and manufacturing runs, which aids to simplify the production procedure and lower lead times. The ability to produce complex geometries with marginal material waste even more adds to set you back financial savings. jig and fixture tooling. Consequently, companies can allocate funds extra efficiently and invest in other locations of their operations. Generally, CNC machining solutions give a trusted path for businesses to boost productivity while preserving high standards in item high quality and efficiency

Convenience in Material Compatibility

The versatility of CNC machining solutions in product compatibility is just one of its most considerable benefits. This ability enables producers Full Report to deal with a diverse array of products, including steels, compounds, and plastics. Each read material can be finely machined to fulfill certain design demands, leading to components that are both useful and high-grade. Aluminum and steel are typically used for their stamina and toughness, while plastics can be picked for their light-weight and corrosion-resistant residential properties. CNC equipments are equipped to take care of different material residential properties, making certain that the preferred specifications are met with precision. This flexibility not just enhances the style opportunities yet likewise allows suppliers to customize their items to various industry needs, from aerospace to automotive and clinical applications. Inevitably, the capacity to efficiently make use of several materials improves the manufacturing procedure and widens the range of ingenious design solutions.

Streamlined Prototyping and Layout Model

Enhancing the prototyping and design iteration procedure is an essential benefit of innovative machining modern technologies. CNC machining solutions enable engineers and designers to rapidly produce precise models, facilitating quick testing and evaluation. This efficiency substantially decreases the moment from idea to production, making it possible for business to repeat designs swiftly based on real-world comments.

CNC machining's high precision reduces mistakes, making certain that each model closely mirrors the final item requirements. The ability to function with various materials better enhances the layout possibilities, permitting complete testing throughout various scenarios.

As an outcome, companies can improve their items better, adjusting to market demands and consumer choices. This responsiveness is crucial in today's competitive landscape, where advancement and rate are paramount. Making use of CNC machining solutions not only accelerates the growth process yet likewise boosts the overall high quality and dependability of the last produced items.

Often Asked Concerns

What Industries Advantage The Majority Of From CNC Machining Solutions?

The aerospace, vehicle, clinical, and electronic devices sectors benefit most from CNC machining services. These industries need high accuracy, complicated styles, and constant high quality, making CNC machining vital for generating detailed parts and meeting strict market standards.

How Does CNC Machining Contrast to Typical Production Approaches?

CNC machining uses higher accuracy, performance, and adaptability blog compared to typical production approaches. It lessens human error, makes it possible for complicated styles, and enables quick prototyping, eventually bring about better production top quality and minimized preparations.

What Kinds Of CNC Machines Are Frequently Utilized?

What Is the Common Preparation for CNC Machining Projects?

The common preparation for CNC machining jobs typically ranges from a few days to several weeks, depending upon aspects like complexity, material schedule, job dimension, and the producer's work, impacting general shipment timelines.

Are There Any Type Of Limitations to CNC Machining Solutions?

CNC machining services do have constraints, including material restrictions, complexity of styles, and dimension restrictions. Additionally, detailed geometries may need customized tooling, which can enhance production time and prices, affecting general task expediency.

CNC machining services provide substantial benefits for accuracy engineering and manufacturing - tool and die maker. As sectors increasingly demand higher requirements, CNC machining solutions have actually arised as a vital remedy for achieving enhanced accuracy and accuracy in engineering applications. CNC machining services not only enhance accuracy yet also considerably enhance efficiency and efficiency in producing processes. CNC machining uses greater effectiveness, precision, and versatility contrasted to conventional manufacturing methods. Commonly used CNC devices consist of CNC lathes, CNC milling machines, CNC routers, CNC plasma cutters, and CNC laser cutters